At Silicon Steels, we pride ourselves as one of the leading manufacturers, suppliers, stockiest, and exporters of duplex steel 2205/31803 plates. These ASTM A240 Duplex 2205 Sheets are extremely durable because they're made from high-quality raw materials. They have high tensile strength and fatigue strength. The Duplex Steel 2205 Sheet / Plate is created by highly skilled professionals who adhere to international norms and guidelines. Its chemical composition includes chromium (up to 23%), nickel (up to 6.5%), molybdenum (up to 3.5%) and silicon (1%). In addition, the plate has high resistance properties against corrosion.

The Duplex Stainless Steel 2205 Cold Rolled Sheet is the best option for pitting and crevice corrosion resistance. The safest temperature range this can be heated at is 1100-1250 degrees Celsius. The UNS S2205 plate provides excellent stress resistance, general corrosion protection, and intergranular immunity. This product comes in lengths of 2000mm, 2440mm, 2500mm, 3000mm or 6000mmm and can be annealed for optimal use.

The Duplex Steel 2205 Sheet is commonly used in chemical industries for applications such as chemical processing units. It can also be used in the construction industry for buildings and bridges. The ASTM A240 Duplex 2205 Plate has many uses in food processing equipment and packaging due to its corrosion resistance properties. Other common uses include pharmaceutical equipment, petrochemical industries, offshore oil drilling companies, and power generation plants.

Duplex steel 2205/ s31803 sheets and plates are highly strong and flexible. They possess excellent qualities that make them versatile in deriving features. The duplex steel 2205 sheets and plates vary in size, shape, and thickness according to the requirement.

Duplex steel is created to resist corrosion and last longer, making it ideal for industrial or commercial use. You can also find this material in many household or semi-commercial applications. Made from only the best quality materials, duplex steel 2205/s31803 sheets and plates are perfect for creating equipment or machinery parts. Often pressure vessels rely on duplex steel for strength and stability too.

Duplex 2205 is an alloy of stainless steel containing 22% chromium, 5% nickel, and 3% molybdenum. It is a ferritic-austenitic stainless steel with a duplex microstructure that offers high resistance to stress corrosion cracking, pitting, and crevice corrosion.

Some of the key features and benefits of Duplex 2205 include the following:

High strength: With a yield strength nearly double that of common austenitic stainless steels, Duplex 2205 is an excellent choice for high-stress applications.Duplex 2205 is highly resistant to chloride stress corrosion cracking, crevice corrosion, and pitting.

Excellent weldability: Duplex 2205 can be readily welded using standard welding techniques with excellent results.

High erosion resistance: Duplex 2205 has a high resistance to erosion and erosion-corrosion, making it appropriate for use in harsh environments.

Excellent formability: Duplex 2205 can be easily cold-worked and shaped, making it suitable for various applications.

Due to its high nickel content, it should be noted that Duplex 2205 is more expensive than other stainless steel alloys. However, its high strength and excellent corrosion resistance make it an ideal material for a wide variety of demanding applications.

Also Look Our:

| Specifications | ASME SA 240/ASTM A 240 |

| Material | Duplex 2205 |

| Standard Sizes | 1000 x 2000 mm, 1220 x 2440 mm, 1500 x 3000 mm, 2000 x 2000 mm, 2000 x 4000 mm |

| Width | 10-2500mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

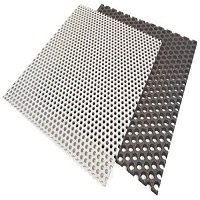

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hairline, sand, blast, Brush, etching, etc |

| SA-240 Duplex 2205 Plate & Sheet Thickness | 0.1mm to 100 mm Thk |

| Hardness | Quarter Hard, Half Hard,Spring Hard, Soft, Hard, Duplex 2205 Sheet suppliers |

| Stock available in form of | Shim Sheet, Rolls, Strip, Flats, Clad Plate, Plain Sheet, Plate, Sheet, Coils, Foils, Rolling Sheet, Rolling Plate, Flat Shim, Flat Sheet, Blank (Circle), soft annealed, sheared, annealed, tread plate,descaled, Checker Plate |

| Profiling | Plasma Plate Cutting Laser Plate Cutting Oxy-propane Flame Cutting |

| Plasma profiles | As per customer's drawings |

| Value added services | Plasma cutting, Waterjet cutting, Laser cutting, welding, edge preparation, etc. |

| Why choose Silicon Steel? | The third party inspection is accepted. Mill Test Certificate is supplied with shipment. |

| Specialized in | ASTM A240 Type Duplex 2205 plate, sheet |

| Delivery time | 7-10 days if in stock. or it is 15-20 days depends to quantity. |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

Duplex 2205 has excellent corrosion resistance, especially chloride-induced stress corrosion cracking. In addition to its resistance to pitting and crevice corrosion, it is suitable for use in various corrosive environments. The alloy's high chromium and molybdenum content provide excellent resistance to general corrosion, while the nickel content improves its resistance to stress corrosion cracking.

The corrosion resistance of Duplex 2205 is superior to that of standard austenitic stainless steel grades, such as 304 and 316, and is roughly comparable to the corrosion resistance of alloy 317L. Compared to other stainless steel alloys, the duplex microstructure of Duplex 2205 offers superior corrosion resistance.

Duplex 2205 has excellent corrosion resistance, but it may be susceptible to corrosion in specific environments, particularly in the presence of chlorides or other aggressive chemicals. To ensure the alloy's long-term performance in corrosive environments, its selection, fabrication, installation, and maintenance must be performed correctly.

Although Duplex 2205 has good heat resistance, it is not as resistant to heat as other stainless steel alloys. It can withstand temperatures up to approximately 260 degrees Celsius (500 degrees Fahrenheit), but its heat resistance decreases at higher temperatures. Duplex 2205 has a lower heat resistance than austenitic stainless steel grades such as 304 and 316 because of its duplex microstructure.

However, Duplex 2205 is suitable for many applications in high-temperature environments due to its excellent heat, high strength, and corrosion resistance. Heat exchangers, pressure vessels, and other equipment requiring high strength and corrosion resistance frequently employ this alloy.

Notably, the heat resistance of Duplex 2205 can be affected by other variables, such as the presence of contaminants, the rate of heating and cooling, and the type of thermal treatment applied. Its selection, fabrication, installation, and maintenance practices must be carefully considered to ensure the alloy's long-term performance in high-temperature environments.

| STANDARD | UNS | WERKSTOFF NR. |

| Duplex 2205/ S31803 | S31803 | 1.4462 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| Duplex Steel S31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 22 – 23 | 3 – 3.5 | 4.50 – 6.50 | 0.14 – 0.20 | 63.72 min |

| Duplex Steel S32205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21 – 23 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

| Density lbm/in3 | Electrical Resistivity mW•in | Thermal Conductivity (BTU/hr•ft•°F) | Heat Capacity BTU/lbm•°F | Electrical Resistivity (in x 10-6) | |

|---|---|---|---|---|---|

| at 68°F | 0.278 | 27.6 | 8.7 | 0.112 | 33.5 |

| at 212°F | 26.1 | 9.2 | 0.119 | 35.4 | |

| at 392°F | 25.4 | 9.8 | 0.127 | 37.4 | |

| at 572°F | 24.9 | 10.4 | 0.134 | 39.4 |

| Product | Price (Per Kg) |

| Super Duplex UNS S32550 Steel Plate | ₹ 200/- |

| ASTM Duplex Steel 2205 Plate | ₹ 300/- |

| Super Duplex Steel 2205 Plate | ₹ 300/- |

| Duplex Steel 2205 Plates | ₹ 750/- |

| Super Duplex Steel Plates | ₹ 550/- |

Welding Duplex 2205 has excellent weldability and can be easily welded using common welding techniques, including Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), and Shielded Metal Arc Welding (SMAW). To prevent cracking, it is essential to control the heat input during welding, particularly in thicker sections. To ensure maximum corrosion resistance, Duplex 2205 welds should also be subjected to a heat treatment after welding.

Duplex 2205 can be heat treated to improve its mechanical properties, but this is rarely required. If heat treatment is required, solution annealing should be followed by rapid cooling. The alloy may also be subjected to a stress relief treatment, but this must be carefully regulated to avoid cracking.

Duplex 2205 can be hot formed using standard hot forming techniques, including hot forging and rolling. To ensure maximum strength and corrosion resistance, hot forming should be conducted at temperatures between 1700°F (925°C) and 2250°F (1230°C), with the correct heating and cooling rates.

Duplex 2205 can be cold-formed using standard cold-forming techniques, including cold rolling and drawing. Cold forming must be performed at room temperature or below to prevent cracking and to ensure maximum strength and corrosion resistance.

Duplex 2205 can be machined less easily than other stainless steel alloys. Utilizing the correct cutting parameters and tool geometries can improve its machinability, but care must be taken to avoid cracking.

Duplex 2205 is highly fabricable and can easily work with standard fabrication techniques, such as bending, stamping, and forming. Essential for preventing cracking and ensuring maximum strength and corrosion resistance is proper fabrication process control. The alloy's high strength makes it suitable for high-stress applications, but it is more challenging to work with than other stainless steel alloys.

Duplex 2205 Plate Metric Dimensions

| Surface finish | Thickness (mm) | Width (mm) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed | 0.25–8.0 | max. 2032 |

| 2D – Cold rolled, heat treated, pickled | 0.4–6.35 | max. 1524 |

| 2E – Cold rolled, heat treated, mechanically descaled | 0.4–8.0 | max. 2032 |

| 2R – Cold rolled, bright annealed | 0.25–3.5 | max. 1524 |

| 2H – Work hardened | 0.4–6.35 | max. 1524 |

| Polished, brushed | 0.5–4.0 | max. 1524 |

Imperial Dimensions of ASME SA 240 UNS S32205 Sheet

| Surface finish | Gauge (in) | Width (in) |

|---|---|---|

| 2B – Cold rolled, heat treated, pickled, skin passed | 10–24 | max. 72* |

| 2D – Cold rolled, heat treated, pickled | 12–24 | max. 60 |

| BA Mexinox only | 18–28 | max. 48 |

| Polished (not brushed) | 11–24 | max. 60 |

| Temper rolled Mexinox only | 13–29 | max. 48 |

| Thickness | Plate Weight per Unit Area | Density |

|---|---|---|

| 3/16 inches | 0.06000 lbs/in²42.184176 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/4 inches | 0.08 lbs/in²56.245568 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/8 inches | 0.121 lbs/in²85.0714216 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/2 inches | 0.161 lbs/in²113.1942056 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 5/8 inches | 0.196 lbs/in²137.8016416 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/4 inches | 0.235 lbs/in²165.221356 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 7/8 inches | 0.274 lbs/in²192.6410704 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 inches | 0.313 lbs/in²220.0607848 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/4 inches | 0.391 lbs/in²274.9002136 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/2 inches | 0.47 lbs/in²330.442712 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 3/4 inches | 0.549 lbs/in²385.9852104 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 inches | 0.627 lbs/in²440.8246392 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/4 inches | 0.705 lbs/in²495.664068 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/2 inches | 0.784 lbs/in²551.2065664 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 3/4 inches | 0.862 lbs/in²606.0459952 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3 inches | 0.941 lbs/in²661.5884936 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

These material are not a single material but the name for a family of corrosion resistant steels. Like many scientific breakthrough the origins of stainless steel lies in a lucky accident. From the smallest part of zipper to the largest building skyscraper, stainless steel is an essential part of modern life.Stainless steel’s strength, resistance to corrosion and low maintenance make it the ideal material for a wide range of applications. It is also has a long life cycle and is 100% recyclable.

We ship our stainless steel metal products in industry leading packaging designed to ensure your order reaches its destination safely. We offer multiple packaging options to meet your specific requirements. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging. We pack our goods in numerous ways based on the products. We pack our products in multiple ways.

To specify the various physical and mechanical properties of the finished product, various tests, both destructive and nondestructive, are performed. Metallurgical, hardness, hardenability, tension, ductility, compression, fatigue, impact, wear, corrosion, creep, machinability, radiography, magnetic particle, ultrasonic, and eddy current are some of the major tests that are performed by quality control personnel. Metallurgical testing is used to determine the quality of steel by analyzing the microstructure of a sample under a microscope. A cross section of a sample is first highly polished and then examined at a magnification from 100-500 diameters. The microstructure of steel consists of grains of different compositions and sizes.